We design, develop and supplyNew Machines & Tooling Parts

For trim & form, singulation, laser marking and precision molding operations.

Get a quote

For trim & form, singulation, laser marking and precision molding operations.

Get a quote

Design high performance machines that are easy to use and compliant to International Standards.

Competitive price with shorter delivery lead time including machine components. We have a huge inventory so that you don't have to keep them.

Design new tooling parts or reverse engineer the ones that you have. You have some options that fit to your budget.

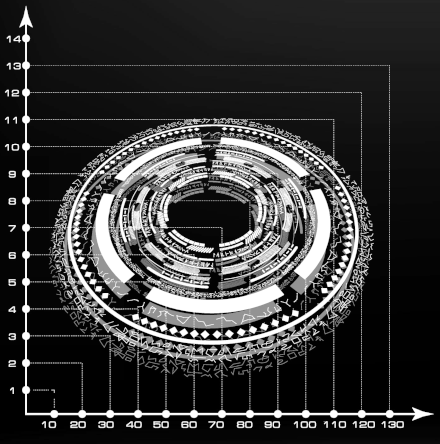

We design this machine with cost and productivity in mind. First, we reduce the need to stop and convert the machine. Less tools means less cost.

When the machine is able to handle high density leadframe, the output will increase tremendously without increasing the machine speed.

Machine specification:

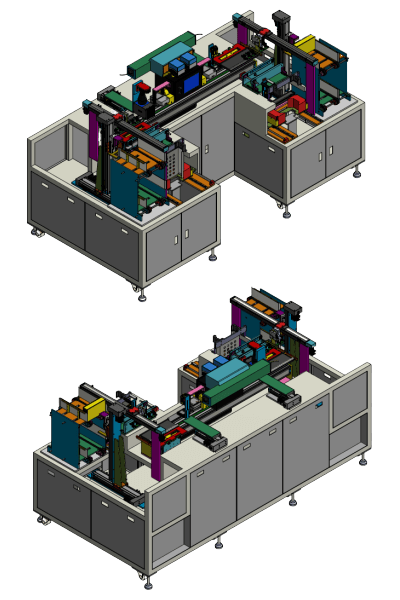

This is a fiber laser developed in Malaysia. It is fast and precise. It provides durable marking that does not wear over time, commonly used for 2D code and IC marking.

The machine is using shuttle type strip handling method, which is best for 100 x 300 mm leadframe products.

Machine specification:

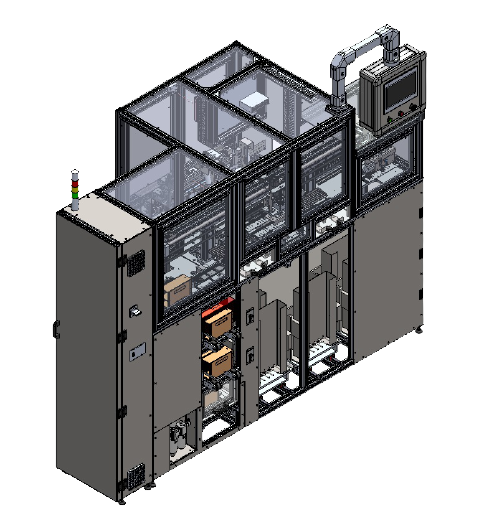

Need integration support? We help you to design and develop material handling system according to your package and machine specifications.

We will then integrate them with your existing machines in the production line. We specialise in:

Loader and Unloader

Machine Linkage and Conveyor

Leverage on our experience and technical know-how to design and build machines based on your requirements. We do this with the following concepts in mind. The machine has to:

Be cost effective

Match production output

Function without or with minimal conversion

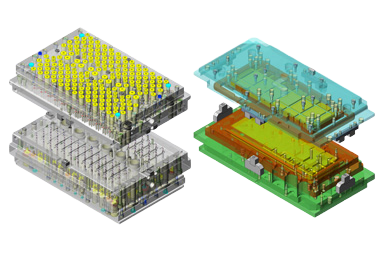

We supply new mold chase for ASM, Towa and Yamaha machines.

We are using the latest EDM technology to fabricate the finest mold chase that is proven to reduce mold cleaning frequency by 30%.

Engineering capability: New design or Reverse engineer

EDM technology: S-EDM

Delivery lead time: 4 weeks

We provide the good quality parts with a short lead time. This allows our customer to reduce their in-house inventory and more savings for them in the long run.

Cost: Lowest in town

Delivery lead time: 2 weeks